Your 2023 Sourcing Strategy Guide for Bags and Accessories

- Benson Li

- Aug 11, 2023

- 7 min read

In order to remain competitive and future-proof, the bags and accessories industry must establish a robust sourcing strategy. This guide provides 6 expert insights, examples of successful practices used by others in your niche as well as key considerations that can help shape your own company's approach to sourcing work overseas.

1. Embrace Sustainable and Ethical Sourcing

A commitment to sustainability and ethical practices is more than a trend– it's a necessary change for businesses worldwide.

1.1 Use Sustainable Materials

Shift towards suppliers offering sustainable materials, such as recycled Polyester (rPET), recycled Nylon, and naturally sourced materials. One leading force in this effort is Patagonia, a renowned outdoor brand that has long been committed to environmental responsibility.

Patagonia holds a strong focus on using recycled materials, including polyester and nylon, in their products. They've been using recycled polyester from plastic bottles since 1993 and today they also source these from garments and leftover fabric. For instance, their Black Hole® Duffel Bag 55L — one of their best selling items — is made of 100% recycled polyester fabric. In the current season, 98% of Patagonia's products is made with recycled materials. They have set a goal to extend this to 100% by 2025, setting a benchmark for the industry.

Consider aligning with suppliers possessing certifications such as the Global Recycled Standard (GRS) to ensure the credibility and efficiency of these recycled materials.

1.2 Prioritize Ethical Suppliers

Position your business to protect human rights and foster positive work environments. To operationalize this, companies should partner with certifiably ethical suppliers who hold standards like SA8000, WRAP and SMETA. These certifications provide business ethical guidelines to ensure respectable practices in the workplace.

SA8000 is one of the world’s first auditable social certification standards encouraging organizations to develop, maintain, and apply socially acceptable practices in the workplace.

WRAP (Worldwide Responsible Accredited Production) focuses on lawful, ethical, and humane manufacturing through its 12 principles which include compliance with laws and workplace regulations, prohibition of forced labor and child labor, and health and safety regulations.

SMETA (Sedex Members Ethical Trade Audit) fosters improvements in ethical and responsible business practices in global supply chains. It covers criteria related to labor standards, environmental management, business ethics, and managing of subcontracting and homeworking.

Fjällräven, the Swedish outdoor brand, exemplifies the drive for ethical sourcing. The company's Code of Conduct mandates their suppliers to provide safe working conditions, reasonable working hours, and fair wages. By preserving the rights of workers and imposing environmentally responsible practices in their supply chain, Fjällräven sets a high standard in ethical sourcing.

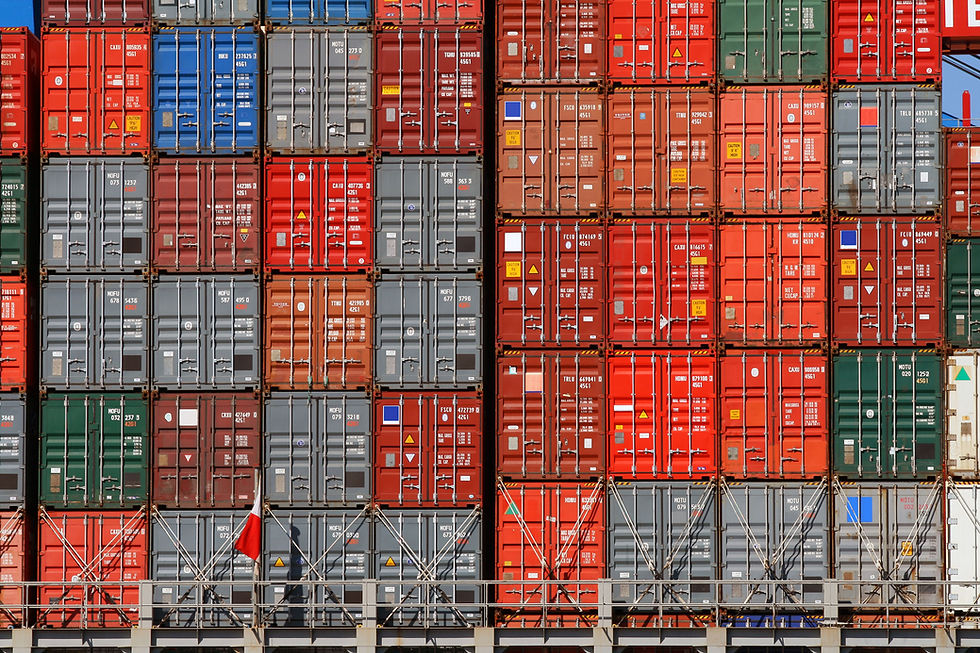

2. Focusing on Supply Chain Diversification

Modern turbulent conditions make supply chain diversification not an option but a necessity.

2.1 Achieve a Regional Balance

Regional balance in sourcing is critical for maintaining business continuity amid unpredictable circumstances. One remarkable example comes from Apple, which has been implementing this strategy amidst the recent global upheavals.

Well-known for its visionary strategies, Apple responded proactively to the disruptions caused by the pandemic. Despite its historical reliance on China for the majority of its production, Apple started diversifying its global manufacturing and supply base.

The push to reduce dependence on China became more pressing during the pandemic when COVID-19 related disruptions at Apple's largest iPhone assembly plant were estimated to have cost the company millions per week. This crisis made clear the risks of having most manufacturing efforts concentrated in one region.

In response, Apple expanded its supply chain beyond China, setting up assembly plants in several other countries including India, Vietnam, and Indonesia. It took substantial steps to shift parts of its manufacturing out of China, revealing the company's commitment to resilience and adaptability.

For instance, it was reported that Foxconn, a major supplier of Apple, expanded Apple production in Vietnam, including MacBooks and future projects. Additionally, Apple has been moving more of its supply chain orders outside of China. Even product lines like the AirPods saw assembly efforts shift, with part of the process beginning in India.

This strategic diversification by Apple reveals how reliance on international and regional suppliers can help maintain supply chain resilience and ensure business continuity, amid business disruptions. Their actions provide insight into how important it is to strike the right balance and diversify sourcing efforts across different regions.

2.2 Ensure Multiple Suppliers

Maintain connections with multiple suppliers per commodity to secure your supply chain during crisis situations. Such connection diversity provides fallback options, ensuring continued production regardless of individual supplier issues.

For example, Samsung's strategy of having multiple suppliers was crucial during the pandemic to sustain their smartphone production. Its wide-ranging network of suppliers across numerous parts of their production process served as a safety net during disruptions. This extensive supplier base, covering everything from raw materials to final production stages, allows them to navigate challenging scenarios with minimal impact on production during the pandemic.

The multi-supplier approach fostered by Samsung demonstrates its purpose of creating a resilient supply chain. It underlines the importance of maintaining relationships with a diverse set of suppliers as a proactive strategy for business continuity.

3. Considering the Total Cost Approach

Considering the complete cost of ownership, material quality and supplier reliability should be as significant to your sourcing strategy as cost mitigation.

3.1 Focus on Quality Over Price

Considering purely the cost in your sourcing decisions can often backfire. Attract customer satisfaction by sourcing high-quality and uniquely designed materials resonating with your brand image. Luxury brands like Hermès and Louis Vuitton have build their reputation on their customers' desires for exclusivity and superior quality.

3.2 Value Supplier Reliability

Reliable suppliers - ones that deliver on time, uphold stringent product quality, and exhibit transparency in their processes, are a crucial asset. For instance, Uniqlo's successful collaboration with Toray Industries shows how trust and transparency can lead to groundbreaking innovations in textiles.

4. Leverage Technology Innovations

To excel in this digital era, harnessing technological advancements to your benefit is key.

4.1 Encourage Use of Digital Supply Chain Platforms

The advantage of real-time information flow between suppliers and purchasers through digital platforms cannot be overstated. This instant communication can allow for quicker adaptation to changing consumer trends. ZARA's renowned agile supply chain is a great example of how digitalization allows for quick adaptation to changing consumer trends.

4.2 Implement Blockchain for Greater Transparency

Blockchain technology can verify ethical and sustainable sourcing claims by providing a transparent record of each step in the supply chain. The De Beers' Tracr blockchain platform, for example, achieves traceability for diamonds in the jewelry industry.

5. Foster Healthy Relationships

Nurturing long-term relationships with suppliers and investing in your workforce development are cornerstones of a robust sourcing strategy.

5.1 Prioritize Supplier Relationships

Investing in long-term partnerships with suppliers come with myriad benefits ranging from cost savings and increased collaboration to concerted problem-solving. The strategic collaboration Japanese automaker Toyota has with its suppliers exemplifies such relationship-building.

Case Study: Toyota and its Suppliers

Known for its disciplined approach towards manufacturing, Toyota's ethos extends to its supply chain management too. Particularly, Toyota extends the spirit of its famed Toyota Production System (TPS) to its supplier relationships, engendering a collaborative and symbiotic partnership.

Toyota's TPS advocates for efficiency, quality, and continuous improvement, ideals that Toyota instills in its suppliers through rigorous training and collaborations. Supplier involvement is not limited to just providing parts. Toyota encourages suppliers to suggest improvements, sparking innovation and enhancing product quality.

Part of this approach involves jointly solving problems. For instance, when facing technical challenges, Toyota and its suppliers collaborate to devise solutions, aligning their expertise to maintain product quality and production efficiency. This strategy paid off during global crises like the Japanese earthquake and tsunami in 2011, where the strong supplier partnerships allowed Toyota to recover more quickly than many rivals.

Moreover, Toyota's approach, by creating a sense of ownership among suppliers, fosters a mutually beneficial relationship. Suppliers become integral contributors to Toyota's car manufacturing process, promoting a stable supply chain and consistent quality.

Toyota's relationship with its suppliers underscores the benefits of maintaining strong, symbiotic relationships with suppliers. Such an approach can enhance product quality, promote innovation, and contribute to the overall resilience of a company's supply chain.

5.2 Invest in Workforce Development

Investing in thorough training equips your employees for more effective partnerships and smarter decision-making implications. This investment engages employees, thereby adding strength to your supply chain operations. This approach is used by companies like Walmart and Amazon that invest in workforce engagement and training to strengthen their supply chain operations.

6. Prioritizing Risk Management and Adaptability

Understanding threatening factors and taking robust actions to adapt quickly can save businesses from severe loss and delays.

6.1 Regular Risk Assessments

Regularly monitor supply chains for risks - be it cybersecurity threats, geopolitical turbulence, natural disasters, or shifts in trade policy.

For example, Nestlé, the world's largest food and beverage company, places great importance on regular risk assessments. These evaluations encompass a variety of areas such as geopolitical changes, environmental hazards, and modifications to trade regulations. By conducting thorough audits of their suppliers with an emphasis on sustainability and safety, Nestlé exemplifies how risk assessment is integral to fostering supply chain resilience and ensuring business continuity.

6.2 Scenario Planning

Develop "what-if" scenarios to make swift decision-making during unforeseen disruptions or crises.

This process proves especially valuable in the Fast-Moving Consumer Goods (FMCG) sector, such as food and beverages. These companies need to handle countless products, each with a unique code known as a Stock Keeping Unit (SKU). Effective SKU management enables these companies to keep pace with the sector's fast-moving market dynamics.

For instance, unanticipated events could include sudden shifts in consumer behavior (due to global health crises or economic downturns), changes in supply chain dynamics (like transportation disruptions), or new regulatory requirements. With "what-if" scenario planning, FMCG companies could effectively respond to fluctuations in demand for various SKUs under different contexts.

Such examples reinforce how "what-if" scenario analysis can provide businesses with timely, effective responses to potential disruptions or evolving market trends.

Conclusion

A comprehensive sourcing strategy is essential in today's global marketplace. Effective sourcing strategies should include:

Sustainable and ethical practices

Diversified supply chains

Total cost-focused approach

Use of modern technology

Strong supplier relationships

Proactive risk management

Orient's Role as A Bag and Backpack Manufacturer

As a prominent bag and backpack manufacturer, Orient incorporates these strategies in its daily operations. We are ready to assist in achieving these strategic goals, offering continuous tailored solutions and support for your business success in the bags and accessories industry. Click here to learn more about us.

Comments